METAL DEPLOYE RESISTOR is developing several innovations in terms of ergonomics, system performance and control methods:

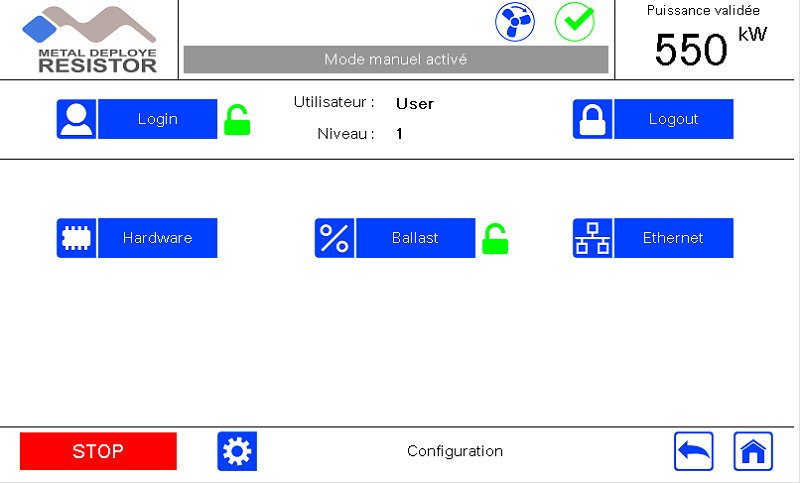

- Control via touch screen locally or remotely (or Modbus)

- Manual or automatic control

- In combination with basic or advanced features

At design stage, our load banks are fitted with a piloting system .

According to your functional needs, two control modes are offered:

- Supervision in “BASIC” mode

- Supervision in “PREMIUM” mode

Depending on your mode of use, several control systems can be recommended:

- One control by illuminated button

- An external command for control from another system

- A Ballasting / deballasting control mode

- The Master Supervision

The automation controls and commands all of the load bank control functions (excluding the generator set).

Supervision is available in French and English . It can be personalized by the customer.

Charging power control by touch screen

All our load banks are fitted with a PLC controlled by an HMI (Human Machine Interface) with color display.

It allows to :

- control load impact

- increase or decrease the power progressively, from zero to the nominal power of the load bank

“BASIC” supervision: manual control, basic functions

This mode allows you to control the load bank directly and manually. All the essential functions to control your load bank are available:

- touch screen control,

- visualization of faults,

- voltage presence indication …

Load control is carried out from a 4.3 inch touch screen .

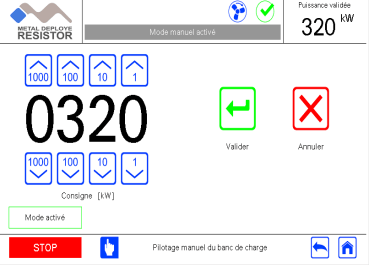

Manual control: handling of loads at the initiative of the operator

The power selection varies from 0 to the nominal power of the load bank. The resolution is given by the smallest power notch.

The selected loads are energized by three-phase contactors.

Input value : power (in kW), a “Validation” button activates the corresponding loads.

If this value is within the possibilities of the load bank, the load engaged will be equal to the setpoint. Otherwise, the load bank will provide the lower load within its possibilities.

A visual alert on the touch screen warns us when a fault is detected.

A window allows you to see the state of the load bank and allows you to acknowledge any faults.

“PREMIUM” supervision: automatic control, advanced functions

This mode, in addition to the functions of the “BASIC” Supervision version, allows:

- additional features

- coupling to an automatic Ballasting / Shedding function (“Ballast” operation). Using a measuring unit, the load bank will detect when the generator set is operating under regime (according to customer data and the information set in the PLC). Thus, it will fill the lack of load to allow the engine to run at a rated power level.

Load control is carried out from a 7 inch touch screen .

The piloting is carried out either directly by an operator in manual mode, or in automatic mode according to pre-recorded recipes.

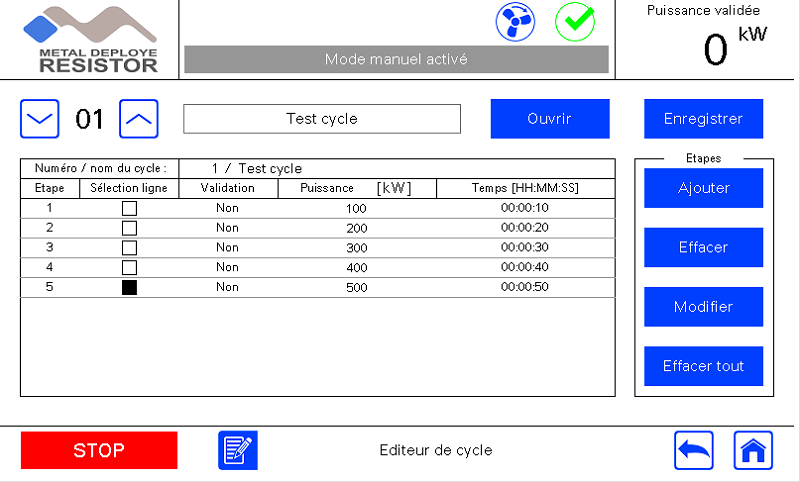

Configuration of charge cycles: recording of recipes

A recipe can be used for any test:

- Input value: power (kW), time (s)

- Storage of 20 cycles of 20 steps with possible looping

- Possibility of requesting validation before moving to the next step

The “PREMIUM” function offers the possibility of having a programmable load bank with automatic test cycles .

Automatic mode: allows you to launch a pre-recorded recipe

Instant reading of the various electrical values of the load bank during the tests.

- Phase currents

- Simple and compound voltages

- Frequency

- Active, reactive and apparent power

- The power factor

These values are available in live visualization and on curves.

Monitoring of the current test - Test values - Curves

Storage of cycle values in CSV format

All the measured values are recorded, retrievable by a USB plug and manageable in EXCEL.

Option: Remote control system

A console equipped with a 7-inch touch screen and an emergency stop is used to control the load bank.

Two cable lengths of 10m or 20m.

The connection is made by plug.

A compartment in the load bank is used to store this console and its cable

Operation, 2 choices:

- The remote control replaces the fixed touch screen on the load bank. It will be the only means of control.

- The local control and the remote control can control the load bank.

Control systems: local, manual or external control

The METAL DEPLOYE RESISTOR range of load banks can be controlled via different control systems.

Local order

The touch screen is integrated into the load bank. In other words, an autonomous control panel is integrated into the load bank. It is equipped with a charge control button and / or control with touch panel.

Manual control with illuminated button

METAL DEPLOYE RESISTOR leaves the possibility of controlling the load bank using an illuminated ON / OFF button.

A button controls a defined load, a simple addition gives the engaged power.

External control by dry contact

This command mode can be used alone or with all types of Supervision.

Here it is the generator which comes to control the load directly on the load bank. Load and ventilation control is available on the terminal block: status information for the power contactors and the motor contactor.

Also available on terminal block:

- Head circuit breaker status

- Ventilation contact feedback

- Remote emergency stop

External control via MODBUS

Modbus TCP / IP Communication is a language protocol between the generator set and the load bank PLC.

The load bank will be controlled by an external control system via an exchange table.

This command mode requires the Supervision command in “Premium” mode.

Automatic ballasting and deballasting included

The automatic ballasting / unloading option allows, via a current transformer, to regulate the load of the bank according to the value of the current consumed by the installation. This variation can be managed with respect to the current delivered by the generator set or with respect to the consumption of the network.

The point is to maintain a minimum load on your generator set during operation to prevent premature wear.

The use of automatic ballast / deballast mode is available via a supervision type control mode.

The supply and installation of the current transformer is not included, a connection terminal block is provided for this purpose in the electrical compartment of the load bank.

MASTER Supervision: simultaneous control of several banks

You have the possibility of controlling several load banks from a single control interface.

This function is intended increase testing capacity by adding the nominal power of each connected load bank.

The operation is identical to the single bank mode.

It is possible to control several load banks simultaneously:

- via a computer (Windows environment)

- via a remote remote control

Features

- Automatic recognition of load banks

- Manual or cycle control

- Display of network parameters and graphical visualizations

- Saving and exporting data

Depending on your needs, 2 remote controls are available:

- Multi-bank remote control : control of up to 4 load banks

- RC48 Performance remote control : control of up to 48 banks, of different technologies and powers

H3 "BASIC" or "PREMIUM": how to choose the right option according to your needs? H3

It is possible to control a load bank remotely using a remote screen or a control case.

Developed by our R&D teams , 2 systems - "BASIC" and "PREMIUM", which can be used via a remote remote control. That is to say, a control case connected to the load bank by a cable and which will allow remote control.

It is an ergonomic facility especially when the test bank are placed for example in a warm room, in height or even outside.

| BASIC MODE | PREMIUM MODE |

|---|---|

| Manual command | Automatic control |

| Basic functions | Advanced functions Cycle, ballast, data management |

|

|

Customization options for a tailor-made load bank

METAL DEPLOYE RESISTOR is at your disposal to define the specific options and equipment related to your needs:

- Need a trailer : road transport trailer equipped with Timon. Weight under 750 kg, without license: see our road trailer for load bank

- Any other customization of your load bank : personalized colors, with cable storage box, storage and transport protections ...: see all our loadbank customization options

- Need for mobility and transport : lifting ring, transport / handling castors, a skid frame (or base with fork passage)… See all the options of moving a load bank