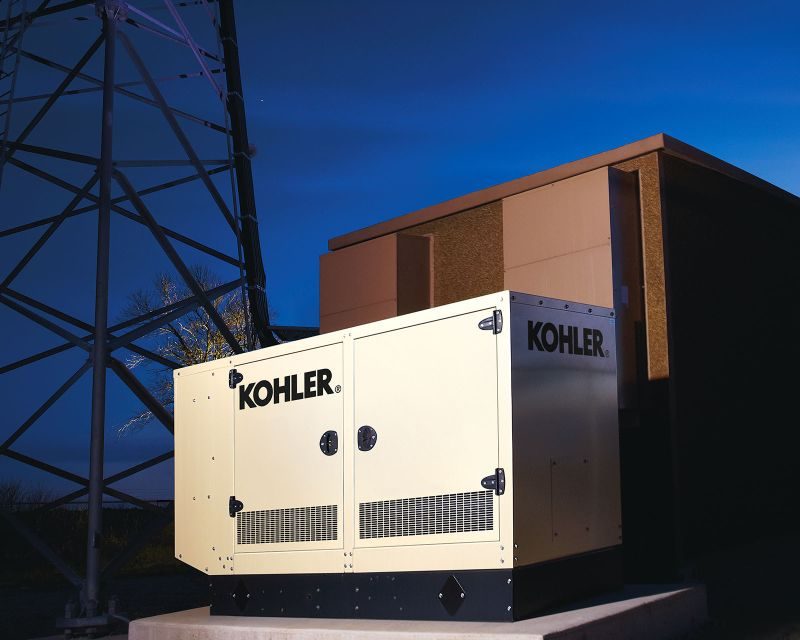

Testimonial from RC, project manager at KOHLER

Context

KOHLER’s search for a load bank for one of its Data Center operator customers

Objective

Find a responsive, reliable and innovative manufacturer to meet the demanding requirements and constraints of the end customer

Project

Tailor-made design of a very compact load bank, capable of absorbing high power levels in a short timeframe

Technical specifications to meet

Data centers are a demanding environment, because a loss of power to the site would be highly problematic. It is impossible for operators not to ensure continuity of service! So there are strong requirements in terms of maintenance quality, load bank reliability, equipment operation, particular attention to ease of use for technicians, and also the need for rapid intervention in the event of a problem.”

A compact but powerful load bank!

One of our customer’s main requirements was to have a very compact product, as space is often at a premium. Generally, we position generators on the roof of data centers, and the same goes for the load bank. However, there is already a lot of equipment present, so space is limited and the footprint has to be reduced as much as possible. In addition to being small in size, the charge bank must withstand high power (2500 kW) and therefore be highly reliable, thanks in particular to a high performance cooling system.

The load bank must also be easy for technicians to operate. It is a sensitive equipment we use frequently, at least once a month. It will be used to test generators and other site equipment such as UPS systems (Uninterruptible Power Supply). These systems are essential for securing the site in the event of a power cut: they make the transition for a few minutes between the power cut and the handover to the genset, thus avoiding a blackout.”

The choice of METAL DEPLOYE RESISTOR

“We chose METAL DEPLOYE RESISTOR, because they met our technical expectations in terms of size, power, noise level, reliability and intervention capacity.. What’s more, they were competitive and within our budget. Finally, the fact that they were produced in France was an added advantage for us, and a real vote of confidence : for example, we could be present during testing if required. The fact that their team was able to take care of commissioning was also a real asset, as most companies subcontract this part of the job, so it was an important point of reassurance.”

Reactivity, a real strength

“What we appreciate most about METAL DEPLOYE RESISTOR is their responsiveness . For our customer, we had to produce precise drawings of the proposed equipment. The documents produced within a short timeframe met our expectations in terms of rendering quality, which enabled us to quickly launch the manufacturing process.

Their in-house design office also enables them to make rapid adaptations when necessary. For example, the standard exhaust air duct was not suited to the installation constraints of our customer. METAL DEPLOYE RESISTOR reacted immediately, and came up with a suitable design with a new duct, this time vertical. They develop products that are adapted and customized to our needs.

Finally, what we really appreciated was their responsiveness when we needed them to intervene on site. They were efficient: their team travelled even far from the head office, whether in the south of France or even in Spain. The intervention team was dispatched, the diagnosis carried out and the solution quickly put in place.”

An intuitive interface

Both our commissioning teams and our customer’s teams have repeatedly told us how easy the product is to use. The Human Machine Interface (HMI) is very intuitive, and with just a little training, the technicians are very quickly autonomous in the use of the load bank, which is a nice surprise!”

A beautiful relationship now established

“We put our trust in METAL DEPLOYE RESISTOR for a first load bank 3 years ago and they equipped other sites we now manage, with 10-foot HC containers: LARA 10 R.

In fact, we’ll definitely be calling on them for future projects!”

About Kohler

Kohler has been designing, manufacturing and installing generating sets from 1 kVA to 3,300 kVA since 1966. The KOHLER brand offers a complete range of portable gensets, industrial generators and rental generating sets.

It also helps its partners and customers to maximise the service life of their continuous or back-up power production installation through after-sales service and the supply of replacement parts. The KOHLER brand is distributed in more than 180 countries via a network of local partners who benefit from continuous support and training in new tools and products.